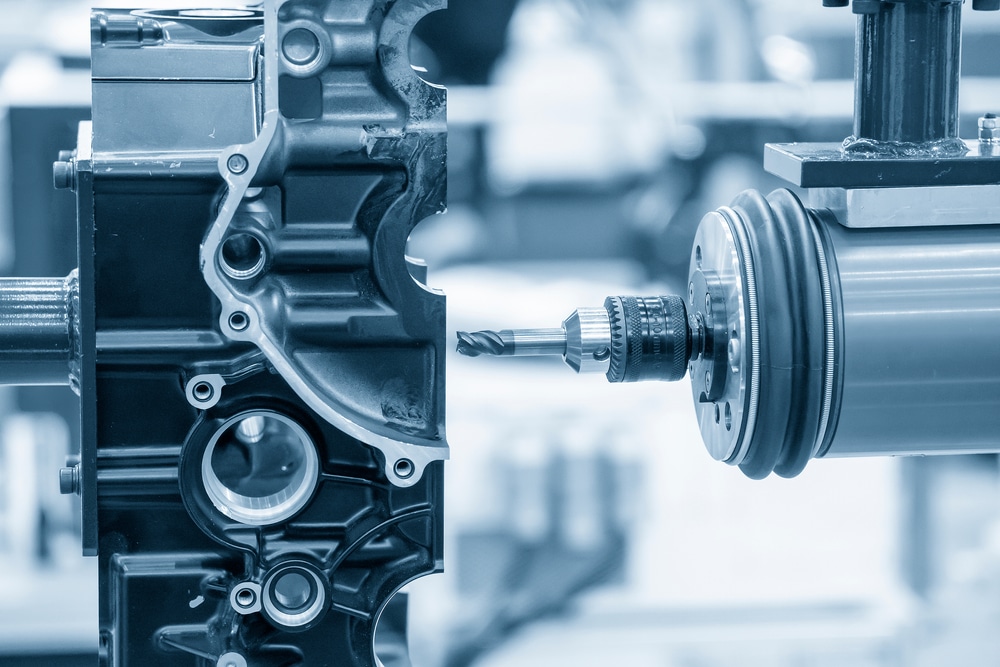

End-of-arm tooling (EOAT), sometimes referred to as end effectors, are devices that can be installed on a robotic arm or wrist, and they’re what expands your industrial robot’s capabilities. There are three major categories, or types of end effectors: automation, process, and inspection/verification.

The latest trends in robotic end-of-arm tooling focus on enhancing safety, versatility, adaptability, and intelligence to meet the increasing demands of automation in various industries.

The latest trends in robotic end-of-arm tooling include:

Collaborative End Effectors

With the rise of collaborative robots (cobots), there is a growing demand for end effectors that can safely work alongside humans. Collaborative end effectors are designed with built-in safety features like force sensing and compliance to prevent injuries during human-robot interaction.

Customization and Flexibility

End effectors that can be easily customized and adapted for various tasks and applications are gaining popularity. This allows robots to be more versatile, as end effectors can be quickly swapped or reconfigured to handle different materials, objects, or processes.

Adaptive Grippers

Grippers that can adjust their shape or grip force based on the objects being handled are becoming more prevalent. These adaptive grippers use advanced sensors and algorithms to automatically adapt to different shapes, sizes, and materials, increasing the efficiency and reliability of robotic handling.

Vision and Sensing Integration

Integrating vision systems and sensors into end effectors allows robots to perceive and react to their environment in real time. This enables precise object detection, handling of complex shapes, and the ability to adapt to dynamic environments and unpredictable object positions.

Lightweight and Compact Design

With the increasing use of lightweight collaborative robots, end effectors that are compact and lightweight have gained significance. These tools allow for higher payload capacity and better robot motion control, resulting in improved overall performance and accuracy.

Innovative Material Handling

End effectors designed specifically for material handling, such as package sorting, palletizing, or bin picking, are being developed. These tools often incorporate advanced software to enable efficient and robust handling of various types of materials, improving productivity in industries like warehousing, logistics, and manufacturing.

End Effectors with Intelligence

End effectors equipped with artificial intelligence capabilities are emerging, enabling them to learn and adapt to new environments and situations. These intelligent tools can optimize their own performance, make autonomous decisions, and improve precision and efficiency over time.

Automation Integration

End effectors that can seamlessly integrate with other automation systems, such as conveyor belts, vision systems, or robotic arms, are becoming more common. This allows for synchronized and automated workflows, reducing the need for manual intervention and enhancing overall productivity.

Overall, custom designing and building specific components for your EOAT can result in a more efficient, adaptable, cost-effective, and safer system. It can also improve the quality of your product and end-user satisfaction. So, if you’re looking to optimize the performance of your system, investing in custom-designed EOAT components is the way forward.

RAM Solutions can custom design and build specific components for your end-of-arm tooling from simple to complex!

Our dedicated team of design engineers and project managers can handle all your projects big or small. Of course, we try to use standard components but can integrate customization to work with your specific needs to ensure your jobs are done in the most efficient manner.

Contact RAM Solutions today to discuss your end-of-arm tooling needs at 248-299-0525.