In today’s rapidly evolving industries, automation is becoming the norm to enhance productivity, accuracy, and overall efficiency. One critical aspect of automation is the use of robotic grippers, which mimic the human hand’s ability to grasp and manipulate objects. We will explore how robotic grippers are transforming various industries and revolutionizing manufacturing processes.

Automotive Industry

Robotic grippers play a vital role in the automotive sector by streamlining assembly lines and performing repetitive tasks with utmost precision. They are capable of reliably gripping and manipulating a wide range of components, from small bolts and screws to larger parts like doors and bumpers. With their ability to adapt and handle different shapes and sizes, robotic grippers enhance production speed while maintaining consistent quality standards.

Electronics and Electrical Industry

In the electronics and electrical industry, delicate and sensitive components require careful handling during manufacturing processes. Robotic grippers equipped with sensors and soft-touch technology can ensure gentle yet secure grip, preventing damage to fragile components. These grippers improve the assembly of complex circuit boards, precise soldering, and accurate placement of components, resulting in higher production yields and reduced rejects.

Pharmaceuticals and Healthcare Industry

Precision and sterility are of utmost importance in the pharmaceutical and healthcare sector. Robotic grippers, with their ability to handle small vials, syringes, and medical instruments, play a vital role in automating processes such as packaging, sorting, and assembly. They ensure consistent quality, reduce contamination risks, and enable faster production rates with minimal errors, ultimately improving patient safety.

Food and Beverage Industry

Efficiency, hygiene, and product integrity are key considerations in the food and beverage industry. Robotic grippers constructed from food-grade materials and equipped with sensors can safely handle perishable food items, bottles, and packaging materials. They increase production rates, reduce human error, and ensure compliance with strict food safety standards.

Logistics and Warehousing

In the logistics and warehousing industry, handling and sorting packages quickly and accurately are essential. Robotic grippers integrated into robotic arms or mobile platforms provide efficient solutions for order fulfillment, palletizing, and packing. With their ability to adapt to various package shapes and weights, robotic grippers enhance supply chain operations, minimizing errors and maximizing productivity.

The use of robotic grippers has revolutionized several industries, enhancing productivity, precision, and efficiency. From automotive assembly lines to pharmaceutical packaging, these versatile tools offer speed, accuracy, and consistency. The ability to handle various components, shapes, and sizes makes robotic grippers a flexible solution for automation needs across industries. As technology continues to advance, robotic grippers will undoubtedly play an increasingly significant role in shaping the future of manufacturing.

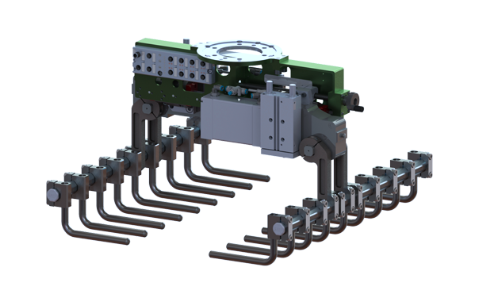

RAM Solutions is an authorized distributor of Applied Robotic’s Grippers. They have several standard versions, but we also work with your needs in customizing grippers. Several accessories like control position switches, safety devices with spring and workpiece stabilizers are also available.

Please reach to the team at RAM Solutions for an online or in-person presentation and demo on Applied Robotic’s latest (FSG) Flexible Smart Gripper! Give us a call today at 248-299-0525 or reach out to us on our contact form.