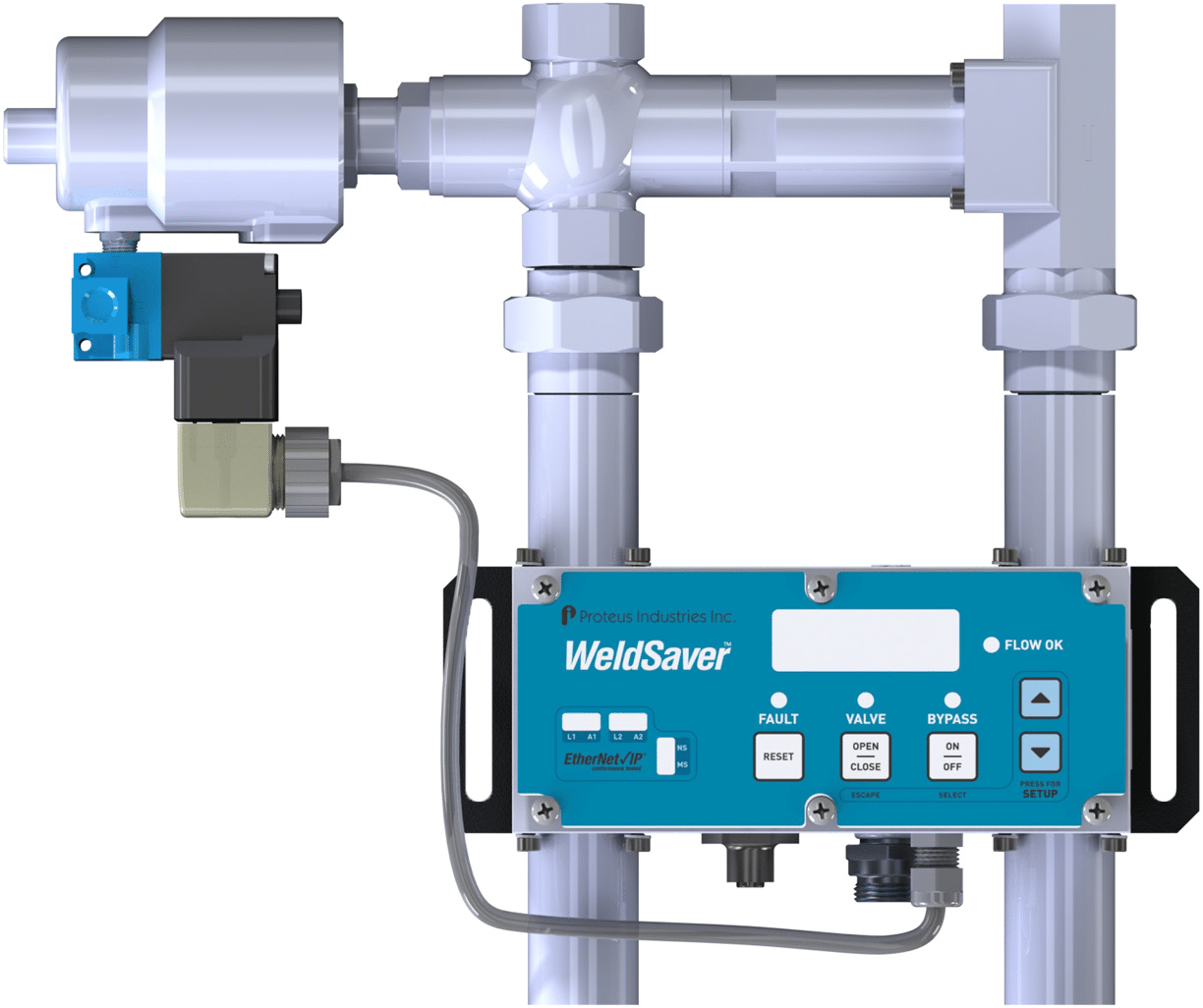

The Weldsaver 6 with eVac Coolant Retraction Module

In the dynamic world of manufacturing and industrial automation, safety and efficiency are paramount. At RAM Solutions, we understand the challenges that come with robotic welding applications. That’s why we’re excited to introduce you to our cutting-edge solution, the Weldsaver 6 with eVac Coolant Retraction Module. This innovative product is a game-changer for flow control, leak detection, and spillage prevention in the world of robotic welding.

The WeldSaver 6: A Revolution in Water-Safety

Our WeldSaver 6 is not just another device; it’s the leading water-safety solution tailored specifically for robotic welding applications. Whether you’re monitoring coolant flow to individual weld guns or managing the cooling circuit for an entire weld cell, the WeldSaver 6 ensures your welding process stays on track by rapidly and reliably detecting changes in flow continuity. These changes can result from slow leaks, cap losses, hose bursts, or other catastrophic events, and can potentially save you from expensive equipment damage and weld cell floor contamination.

Real-Time Information at Your Fingertips

One of the standout features of the WeldSaver 6 is its user-friendly graphical interface. With clear visual indicators and descriptions, you can monitor the device status in real time. Accessible over a network using most JavaScript-enabled web browsers, simply enter the working IP address of the device to stay informed and in control.

eVac Coolant Retraction Module: Keeping Equipment Dry

The eVac Coolant Retraction Module is an integral part of the WeldSaver 6, and it plays a crucial role in keeping your expensive equipment dry. When a cap change or cap loss occurs, this module swiftly redirects coolant flow, preventing spills and damage. In fact, it can shut off flow in less than 1 second after a cap loss, ensuring that your equipment remains protected.

Continuous Monitoring for Optimal Performance

The WeldSaver 6 doesn’t just prevent spills; it also ensures that your welding process operates at its best. It continuously monitors and communicates coolant flow and temperature conditions, guaranteeing that your electrodes remain adequately cooled. With its proprietary leak-detection algorithm, which is independent of flow calibration, it can send an alarm to the weld controller in less than 0.4 seconds if a leak is detected.

Customizable and Compatible

We understand that every welding application is unique. That’s why the WeldSaver 6 offers user-selectable operating parameters and alarm settings, allowing you to tailor it to your specific needs. You can also remotely control the valve and system state to support gun chargers and weld-cap changes, providing you with flexibility and control.

Integration and Connectivity

For seamless integration into your robotic welding setup, the WeldSaver 6 is compatible with robotic teach pendants through a network connection. It also offers EtherNet/IP and PROFINET control interface options, ensuring that it fits seamlessly into your existing infrastructure.

Specifications to Meet Your Needs

With flow ranges from 6-50 LPM (1.5-13 GPM) and the ability to handle liquid temperatures from 4.0-110°C (39-230°F), the WeldSaver 6 is versatile enough to meet the demands of various robotic welding applications.

Intelligent Leak Detection

Our proprietary detection algorithm is the heart of the WeldSaver 6. It rapidly identifies subtle flow velocity changes that distinguish true leaks from other effects, ensuring that leaks are positively identified in less than 0.3 seconds. In the event of a cap loss or leak, the WeldSaver 6 signals a state change to immediately halt the weld process while simultaneously closing an attached shutoff valve, preventing any further damage or contamination.

RAM Solutions | WeldSaver 6 with eVac Coolant Retraction Module

In the world of robotic welding, the WeldSaver 6 with eVac Coolant Retraction Module stands as a beacon of safety and efficiency. It’s a comprehensive solution that not only protects your equipment but also ensures that your welding process operates at its best. With its intelligent leak detection, customizable settings, and compatibility with existing systems, it’s a vital addition to any robotic welding setup. When it comes to safeguarding your investments and maintaining productivity, RAM Solutions has you covered with the WeldSaver 6.

To learn more about how we can help with your production needs, give us a call at (248) 299-0525 or send in an online contact form today!